Mish won the tender for cleaning sludge from fuel tanks with innovative technology

For the first time, an Israeli company will use an automatic cleaning system without human contact that prevents air and environmental pollution and enables reduction of work time and costs, for cleaning fuel tanks

From: infospot system

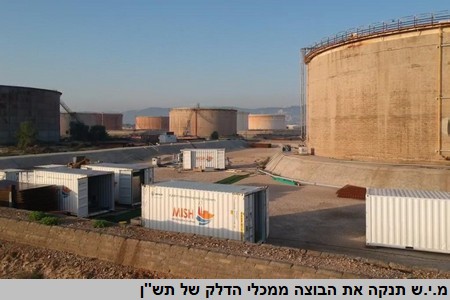

Published on: 6/18/2019The MIS company won the tender for cleaning fuel and oil tanks of the government company for oil and energy infrastructures Ltd. (2008). This is the first time that an Israeli company will clean containers with an advanced technological system without human contact or opening the containers.

It is about cleaning 2 crude fuel tanks, which were built in the thirties of the last century by the British and have been in use ever since. The fuel tanks are about 38 meters in diameter each and store about 1,100 cubic meters of sludge that must be removed. According to preliminary estimates, the cleaning work will last about two months for each tank, of which two weeks will be dedicated to setting up and connecting the system to the tank, and three weeks will be dedicated to continuously cleaning the sludge 24/7.

Reducing pollutant emissions into the air during cleaning

The cleaning of the fuel tanks will be done with advanced technology that will allow the cleaning of the mud and oil from the crude fuel storage tanks, automatically, without leaving the fuel tanks open, so that emissions of fuel vapors into the air during cleaning are significantly reduced. Besides, the safety advantage of cleaning the tanks without the need for workers to enter the tank.

The BLABO system of the Danish company ORECO is intended for cleaning large fuel storage tanks, especially crude oil or fuel oil that are difficult to clean, and was designed to clean tanks with a lot of sludge and oil deposits and they have a floating or fixed roof.

The significant advantage of the BLABO system stems from the reduction of pollutant emissions into the air, which rise in conventional cleaning, such as volatile organic substances, some of which are considered carcinogenic. Since the container is not opened for cleaning, the leakage of gases and toxic substances into the air is avoided. At the same time, all the sludge and oil and fuel residues that are pumped, are transported in a closed system to a closed reservoir near the tank, for treatment and purification, it is also not exposed to the air and without emissions.